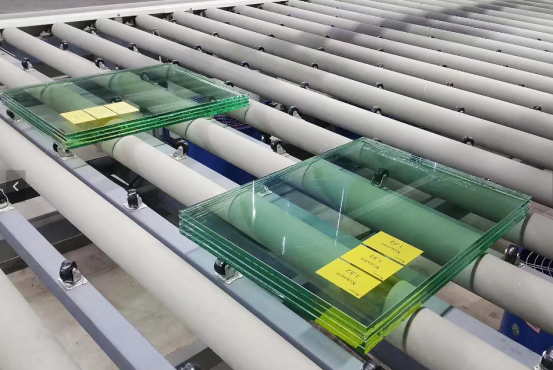

High - Precision Lamination with Autoclave Free Glass Laminating Machines

For the production of glass, precision in lamination is now a requirement and no longer a luxury as the requirements of glass products for various industries are increasingly sophisticated. Autoclave free glass laminating machines have proved to be the key game-changer in the glass industry through precise high-precision lamination. These cutting-edge machines are creating new benchmarks of quality and precision in glass lamination, bestowing many benefits on manufacturers as well as consumers.

Advanced Control Technology: The Key to Precision

At the heart of the high-precision lamination that non autoclave laminated glass machines offer is their high-technology control. The machines feature highly sensitive sensors and intelligent algorithms that monitor and control key parameters of the lamination with amazing precision. Temperature control, for example, is critical in glass lamination because even small fluctuations in temperature can affect the bond and integrity of the layers. Non autoclave laminated glass equipment can maintain temperature within a very narrow range so that the interlayer material is bonded to the glass sheet in a perfect way. Pressure is also a critical parameter, and such machines can apply even and precisely measured pressure over the entire surface of the glass, with no chance of uneven lamination characteristic of traditional autoclave-based systems.

High-precision lamination achieved through autoclave free glass laminating machine finds specific application in fields such as electronics and automotive.

Precision Lamination within the Electronics Industry

In electronics, glass components used in smartphones, tablets, and other devices are thin and delicate, and accuracy is critical. Even a slight defect in the lamination process will result in display problems or impaired functionality. Autoclave free glass laminating machines can handle these delicate glass components with care and laminate with high precision. They can precisely layer multiple layers of glass and interlayers so that the final product possesses the high quality required for high-end electronics.

Precision Lamination in the Automotive Industry

In the automotive industry, high-precision lamination is necessary for the production of windshields and other automotive glass components. Windshields in newer vehicles are including embedded sensors, heating elements, and noise-reducing layers. Autoclave free glass laminating equipment can accurately position and bond these additional features during lamination, so that the end product will function perfectly. Having the capability to ensure constant precision also means that manufacturers can produce windshields with consistent quality, defects are less probable, and overall safety is enhanced.

Advantages over Traditional Autoclave Lamination

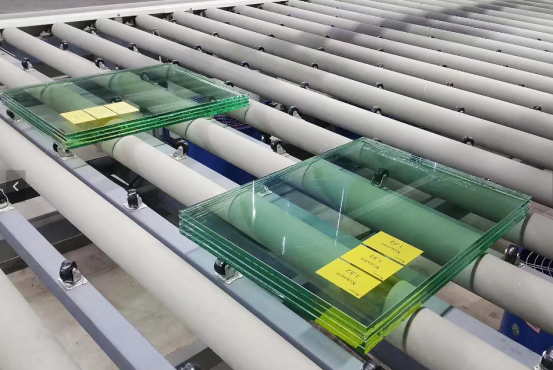

Autoclave free laminate machines have several distinct advantages over traditional autoclave-based lamination processes. Autoclaves utilize a wide chamber, and it is hard to maintain even pressure and temperature within the chamber. This may cause inconsistency in the lamination quality, particularly in large glass panels. Autoclave free laminate machines employ a more focused and localized method of lamination. to have more liberty to work with different shapes and sizes of glass.

Adaptability to Various Laminating Needs

Additionally, non autoclave laminated glass machines are capable of adjusting to different laminating requirements. Through their programmable control systems, manufacturers can easily switch between different laminating settings for different glass products. Whether laminating thick architectural glass or thin optical glass,these machines can be adjusted to achieve the best lamination results. This adaptability combined with high-precision capabilities makes autoclave-free glass laminators an indispensable piece of equipment in the modern glass manufacturing industry.

Conclusion

In short, the autoclave free laminate machine has revolutionized the process of glass lamination to a large extent by making high-precision lamination possible. Its advanced control technology, flexibility to be applied in different industries, and superiority over traditional methods make it the first choice among manufacturers who want to produce high-quality glass products. Since the demand for precision engineered glass continues to grow, these machines will definitely play an important role in shaping the future of the glass manufacturing industry. If you would like to purchase this equipment, please contact me and we will respond within 12 hours.

-

Non Autoclave Glass Laminate Machines: Shaping the Aviation Sector with High - Performance Glass for Cockpits and Cabin Windows

In the demanding aviation industry, quality and performance of aircraft material are of utmost importance.Among others, glass applied for cockpit and cabin windows must comply with stringent requirements of safety, endurance and optical performance. Non autoclave laminated glass machines have been the game-changer in this industry, upsetting the entire process of production of high-performance aviation glass.2025-04-28

-

Autoclave Free Glass Laminate Machines: Enhancing Marine Applications with Durable and Weather - Resistant Glass

The harsh and demanding marine environment brings unique challenges to the materials used in ships and offshore structures. Glass parts, particularly, need to be resistant to extreme weather conditions, seawater corrosion, and mechanical stress. Autoclave free glass laminate machines are a highly effective solution that can deliver robust and wind-resistant glass, significantly improving functionality and safety for marine applications.2025-04-25

-

Powering Auto Glass with Non Autoclave Laminate Machines

In the ever-evolving era of automobiles, the quest for innovation in material and manufacturing processes never ends. The craft of glass component production has evolved significantly. Non autoclave laminate machines enable the manufacture of light and very secure glass components with the stringent requirements of modern automobiles.2025-04-24

-

Autoclave Free PVB Laminating Machines: Meeting the Demands of Modern Architecture

In the dynamic field of modern architecture, the pursuit of innovation, functionality and beauty has redefined the standards of building materials. As the cornerstone of contemporary architecture, glass now not only has to assume structural functions, but also needs to take into account energy efficiency and visual beauty. As a machine for glass processing, the autoclave free pvb laminating machine suits the diverse and demanding needs of modern construction projects.2025-04-23