Exploring the Efficiency of Autoclave Free Laminate Technology

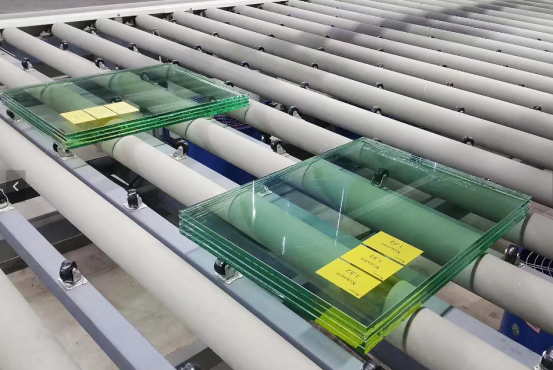

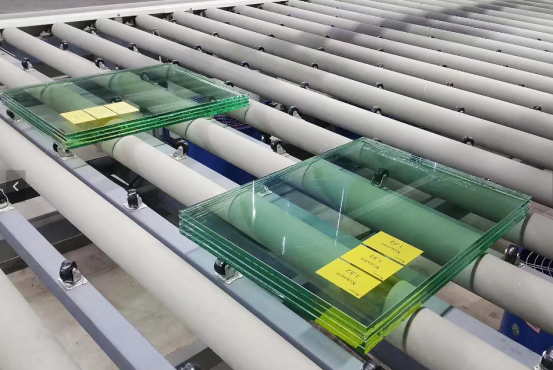

In the field of glass lamination, pursuit of more efficient technology has led to the development and exploration of autoclave free lamination technology. They include EVA film laminate machine, PVB film laminate machine and SGP film laminate machine. Autoclave-free glass laminate machines have shown enormous potential in transforming the lamination process, which can allow glass enterprises to achieve better production efficiency and cost reduction, and have been in great demand.

Energy-saving Efficiency

One of the best advantages of autoclave free laminate machine technology is that it is extremely energy efficient. Traditional autoclave-based lamination technology requires the autoclave to be raised to a very high temperature and maintained at a specific level of pressure for a long duration of time. A tremendous amount of energy is consumed in the process. Autoclave-free laminate EVA glass laminate machine works differently from the traditional one. It uses a more energy-saving, advanced pressure and heating system. Some EVA glass laminate machines use induction heating technology, and it can directly heat the glass and EVA film, with reduced energy loss. Non autoclave glass laminate machines also have a less complex heating system. Compared to autoclaves, it can reach the required temperature for lamination faster. It has been proven through research that factories of laminator glass that are autoclave-free can conserve as much as 40% of energy during the lamination process, which besides reducing operational expenses, also assists in environmental sustainability.

Production-time Efficiency

Non autoclave glass laminate machine technology also outperforms in saving time during production and increasing efficiency. Traditional autoclave glass laminators take time to heat up, reach the right pressure, and then cool down after the lamination process. This heating and cooling cycle is time-consuming. In contrast, laminators like non autoclave glass laminator can start laminating work much faster. They don't have to wait for the lengthy preheating and pressurizing processes like autoclaves. For example, a non autoclave glass laminator can make laminated glass in minutes, while an autoclave will take hours to reach the appropriate environment. This saves preparation time and allows for more production capacity. For a big glass-making company, this means more laminated glass products are manufactured in a day, which means overall productivity is higher.

Quality-control Efficiency

For quality control efficiency, autoclave-free lamination technology also has its own advantages. For example, EVA glass laminating machine can precisely control temperature and pressure during the lamination process. This precise control ensures a more consistent bond between the glass layer and the EVA interlayer. The resulting laminated glass has fewer defects, such as bubbles or uneven adhesion. The non-autoclave glass laminators also tend to be equipped with advanced sensors and control systems. Such systems can monitor the lamination process in real time and make adjustments. Such real-time monitoring and adjustability guarantee that there are high standards of quality being adhered to in the production process. However, for the autoclave-based laminated end product, due to the complexity of the autoclave's heating and pressure control system, the quality can be more variable. The quality of the products produced by non-autoclave laminators will be more stable.

Cost - effectiveness Efficiency

The efficiency of autoclave-free lamination technology also manifests itself in cost benefits. Reduced energy consumption and increased production time efficiency directly lead to lower operating and production costs. Additionally, autoclave free laminate machines are less demanding to maintain compared to autoclaves. Autoclaves have complicated mechanical and heating components that are exposed to wear and tear, which means increased maintenance costs. On the other hand, in the majority of cases, non-autoclave glass laminators are simpler and easier to maintain. The lower maintenance cost, combined with other efficiency-related cost savings, makes autoclave-free lamination technology a reasonable alternative for glass manufacturers that desire to maximize their bottom line.

In short, non autoclave laminate machine technology represented by EVA glass laminating machines has a number of efficiency advantages in energy saving, production time, quality control and cost. As technology continues to advance, it is playing an increasingly larger part in the glass laminating industry, making it possible for manufacturers to produce high-quality laminated glass products more cost-effectively and sustainably. For more information on non-autoclave glass laminators, get in touch with us.

-

Non Autoclave Glass Laminate Machines: Shaping the Aviation Sector with High - Performance Glass for Cockpits and Cabin Windows

In the demanding aviation industry, quality and performance of aircraft material are of utmost importance.Among others, glass applied for cockpit and cabin windows must comply with stringent requirements of safety, endurance and optical performance. Non autoclave laminated glass machines have been the game-changer in this industry, upsetting the entire process of production of high-performance aviation glass.2025-04-28

-

Autoclave Free Glass Laminate Machines: Enhancing Marine Applications with Durable and Weather - Resistant Glass

The harsh and demanding marine environment brings unique challenges to the materials used in ships and offshore structures. Glass parts, particularly, need to be resistant to extreme weather conditions, seawater corrosion, and mechanical stress. Autoclave free glass laminate machines are a highly effective solution that can deliver robust and wind-resistant glass, significantly improving functionality and safety for marine applications.2025-04-25

-

Powering Auto Glass with Non Autoclave Laminate Machines

In the ever-evolving era of automobiles, the quest for innovation in material and manufacturing processes never ends. The craft of glass component production has evolved significantly. Non autoclave laminate machines enable the manufacture of light and very secure glass components with the stringent requirements of modern automobiles.2025-04-24

-

Autoclave Free PVB Laminating Machines: Meeting the Demands of Modern Architecture

In the dynamic field of modern architecture, the pursuit of innovation, functionality and beauty has redefined the standards of building materials. As the cornerstone of contemporary architecture, glass now not only has to assume structural functions, but also needs to take into account energy efficiency and visual beauty. As a machine for glass processing, the autoclave free pvb laminating machine suits the diverse and demanding needs of modern construction projects.2025-04-23